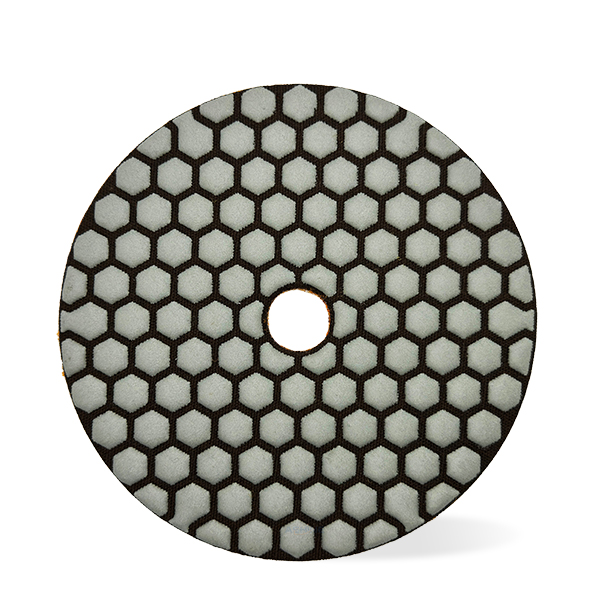

Dry Resin-bond Honeycomb Polishing Pad

Details

This honeycomb polishing pad is specially designed for granite, marble, artificial stone, engineering stone, ceramic tile, etc.

The honeycomb dry polishing pad is self-adhesive on the hoop and loop back sanding pad, and color-coded helps distinguish different grits during operation.

The pad has large channels for superior dust evacuation.

Ashine uses a special diamond powder with an uneven electroplated surface to have a strong bond with resin.

Different mess sizes are available

Advantages

Fast dry polishing and strong grinding force, with no burn during the implementation process

Good durability and a longer lifetime.

Excellent clarity, gloss, and soft degree

Extremely flexible for the edging and corner polishing

Application

It is suitable for grinding stone, ground tile, ceramic—also a good choice for stone polishing, line chamfer, the arc plate, and special-shaped stone processing.

The honeycomb pads are also recommended for processing, repairing, and renovating marble, concrete, cement floor, terrazzo, glass ceramics, artificial stone, tiles, glazed tiles, vitrified tiles.

Maximum speed 4500 RMP available when implementing the honeycomb polishing pad.

Create high-quality shine on concrete floors, natural stone, granite, engineered or manufactured stone, quartz surfaces, marble, terrazzo with the dry polishing pad.

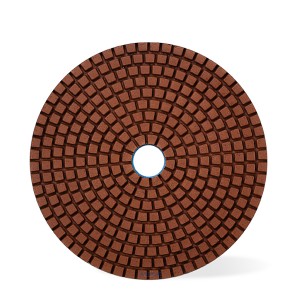

Use the dry polishing pad from coarse to fine during the final polishing. It is ideally used for dry polishing but can be used for wet polishing as well.

Dry polishing is convenient while need to have the dust managed. In contrast, wet polishing eliminates harmful dust and makes a messy slurry difficult to clean up. Either method gives the same finished result. Therefore, the best construction solution is derived from every different construction environment.

Specifications

|

Item No. |

Diameter Inch/mm |

Grit |

|

RVQ03M# |

3”/80mm |

50-3000# |

|

RVQ04M# |

4”/100mm |

50-3000# |

|

RVQ05M# |

5”/125mm |

50-3000# |

|

RVQ06M# |

6”/150mm |

50-3000# |