Fixed Competitive Price Concrete Polishing Disc – Dry Resin-bond Honeycomb Polishing Pad – Ashine

Fixed Competitive Price Concrete Polishing Disc – Dry Resin-bond Honeycomb Polishing Pad – Ashine Detail:

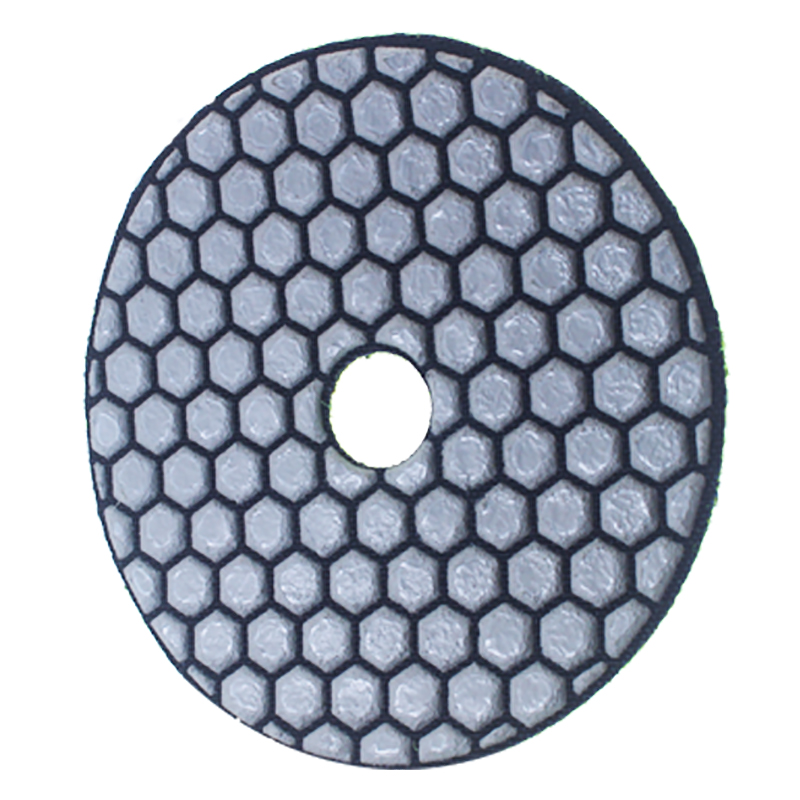

This honeycomb polishing pad is specially designed for granite, marble, artificial stone, engineering stone, ceramic tile, etc.

The honeycomb dry polishing pad is self-adhesive on the hoop and loop back sanding pad, and color-coded helps distinguish different grits during operation.

The pad has large channels for superior dust evacuation.

Ashine uses a special diamond powder with an uneven electroplated surface to have a strong bond with resin.

Different mess sizes are available

Applications

It is suitable for grinding stone, ground tile, ceramic—also a good choice for stone polishing, line chamfer, the arc plate, and special-shaped stone processing.

The honeycomb pads are also recommended for processing, repairing, and renovating marble, concrete, cement floor, terrazzo, glass ceramics, artificial stone, tiles, glazed tiles, vitrified tiles.

Maximum speed 4500 RMP available when implementing the honeycomb polishing pad.

Create high-quality shine on concrete floors, natural stone, granite, engineered or manufactured stone, quartz surfaces, marble, terrazzo with the dry polishing pad.

Use the dry polishing pad from coarse to fine during the final polishing. It is ideally used for dry polishing but can be used for wet polishing as well.

Dry polishing is convenient while need to have the dust managed. In contrast, wet polishing eliminates harmful dust and makes a messy slurry difficult to clean up. Either method gives the same finished result. Therefore, the best construction solution is derived from every different construction environment.

Advantages

Fast dry polishing and strong grinding force, with no burn during the implementation process

Good durability and a longer lifetime.

Excellent clarity, gloss, and soft degree

Extremely flexible for the edging and corner polishing

Specification

|

Item No. |

Diameter Inch/mm |

Grit |

|

RVQ03M# |

3”/80mm |

50-3000# |

|

RVQ04M# |

4”/100mm |

50-3000# |

|

RVQ05M# |

5”/125mm |

50-3000# |

|

RVQ06M# |

6”/150mm |

50-3000# |

|

#=Grit |

||

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Fixed Competitive Price Concrete Polishing Disc – Dry Resin-bond Honeycomb Polishing Pad – Ashine , The product will supply to all over the world, such as: Georgia, Accra, Nigeria, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!